|

Zhejiang Jinggong Science and Technology Co.,Ltd.

|

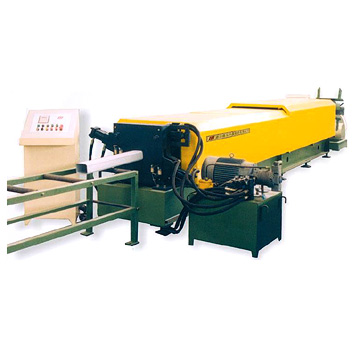

HS-134 Down Pipe Forming Machines

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

This down pipe forming machine mainly consists of a decoiler, roll forming

system, cutting equipment, protective guard, hydraulic system, control s

This down pipe forming machine mainly consists of a decoiler, roll forming

system, cutting equipment, protective guard, hydraulic system, control system,

and product supporter. Curving pipe forming machines are complementary

equipment for these machines, and can make curves for down pipe to meet the requirement of practical engineering projects.

Specifications:

1) Suitable raw material: 0.5mm colored steel sheet

2) Main motor power: 3kW

3) Hydraulic power: 7.5kW

4) Forming speed: 8 - 10m/min

5) Number of roll stands: ~20 stands

6) Control system: Mitsubishi PLC

7) Cutting die material: Cr12 mold steel, with quench treatment

8) Machine dimensions: 16 x 1.1 x 1.2m

Workflow:

Decoiling - coil sheet guiding and feeding - roll forming - cut to

length - product packaging (manual)

Outer Packing:

Main machine body is naked loaded, some spare parts are loaded in wooden cases

system, cutting equipment, protective guard, hydraulic system, control system,

and product supporter. Curving pipe forming machines are complementary

equipment for these machines, and can make curves for down pipe to meet the requirement of practical engineering projects.

Specifications:

1) Suitable raw material: 0.5mm colored steel sheet

2) Main motor power: 3kW

3) Hydraulic power: 7.5kW

4) Forming speed: 8 - 10m/min

5) Number of roll stands: ~20 stands

6) Control system: Mitsubishi PLC

7) Cutting die material: Cr12 mold steel, with quench treatment

8) Machine dimensions: 16 x 1.1 x 1.2m

Workflow:

Decoiling - coil sheet guiding and feeding - roll forming - cut to

length - product packaging (manual)

Outer Packing:

Main machine body is naked loaded, some spare parts are loaded in wooden cases

Related Search

Down Pipe Forming Machine

Bops Forming Machines

Eps Forming Machines

Steel Forming Machines

Plastic Vacuum Forming Machines

Down Pipe Machine

More>>

Find more related products in following catalogs on Hisupplier.com

Related Products

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35